1. Powder Spraying Paint Lines Systems Components and Structure

A Powder Spraying Paint Lines System integrates multiple stations for surface preparation, powder application, curing, and quality control. Key components include a pre-treatment zone (cleaning, phosphating), electrostatic spray booth, conveyor system, curing oven, and recovery unit. Advanced systems feature robotic arms for precision spraying, PLC controls for process automation, and IoT sensors for real-time monitoring. Modular designs allow customization for high-volume production or specialized coatings.

2. Industrial Uses of Powder Spraying Paint Lines Systems

These Powder Spraying Paint Lines Systems are pivotal in automotive manufacturing (car bodies, chassis), appliance production (refrigerators, washing machines), and architectural metalwork (aluminum façades). They also serve aerospace (turbine blades), electronics (server racks), and furniture industries. High-efficiency lines ensure uniform, durable finishes compliant with ISO 12944 and ASTM standards.

3. Powder Spraying Paint Lines Systems Pricing Factors

Manual lines start at 50,000,semi−automatedsystemsrangefrom150,000–500,000,andfullyautomatedlineswithroboticsexceed1 million. Costs depend on line length (e.g., 20–100 meters), throughput (100–1,000 parts/hour), and features like energy recovery or AI-driven defect detection.

4. Best Practices for Operating Powder Spraying Paint Lines System

Surface Prep: Degrease and apply iron phosphate coatings for adhesion.

Spray Parameters: Set voltage (60–100 kV) and airflow (0.5–1.5 bar) based on part geometry.

Curing: Bake at 180–220°C for 10–25 minutes; monitor with IR thermocouples.

Maintenance: Clean filters weekly, inspect nozzles daily, and recalibrate robots quarterly.

5. How to Select Powder Spraying Paint Lines Systems

Production Scale: Choose batch systems for low volume or continuous lines for mass production.

Coating Type: Verify compatibility with epoxy, polyurethane, or fluoropolymer powders.

Automation: Prioritize PLC-controlled systems with SCADA integration for data tracking.

Certifications: Ensure compliance with OSHA, CE, and NFPA 33 standards.

6. Safety Measures for Powder Spraying Paint Lines

Ventilation: Install explosion-proof exhaust systems to mitigate combustible dust risks.

PPE: Mandate respirators (NIOSH N95), anti-static suits, and safety goggles.

Grounding: Maintain <1 ohm resistance to prevent electrostatic discharge.

Fire Safety: Use CO2 suppression systems near powder storage areas.

7. Design Efficiency in Powder Spraying Paint Lines

Modern systems reduce energy consumption by 30% via heat recovery ovens and variable-speed conveyors. IoT-enabled diagnostics predict maintenance needs, cutting downtime by 40%. Compact layouts optimize floor space, while stainless steel construction ensures longevity in harsh environments.

8. FAQs on Powder Spraying Paint Lines Systems

Q: What distinguishes powder spraying paint lines from traditional painting?

A: Powder systems eliminate solvents, reduce waste by 95%, and provide thicker, more durable coatings.

Q: Can these lines handle mixed-material substrates?

A: Yes, with adjustable settings for metals, plastics, and composites using conductive primers.

Q: How to maintain consistent coating quality?

A: Regularly calibrate spray guns, monitor oven temperatures, and use inline thickness gauges.

Q: Are powder spraying lines eco-friendly?

A: Zero VOC emissions and high overspray recovery align with EPA and REACH regulations.

Q: What ROI can businesses expect?

A: Most lines achieve payback within 2–3 years via reduced material costs and higher productivity.

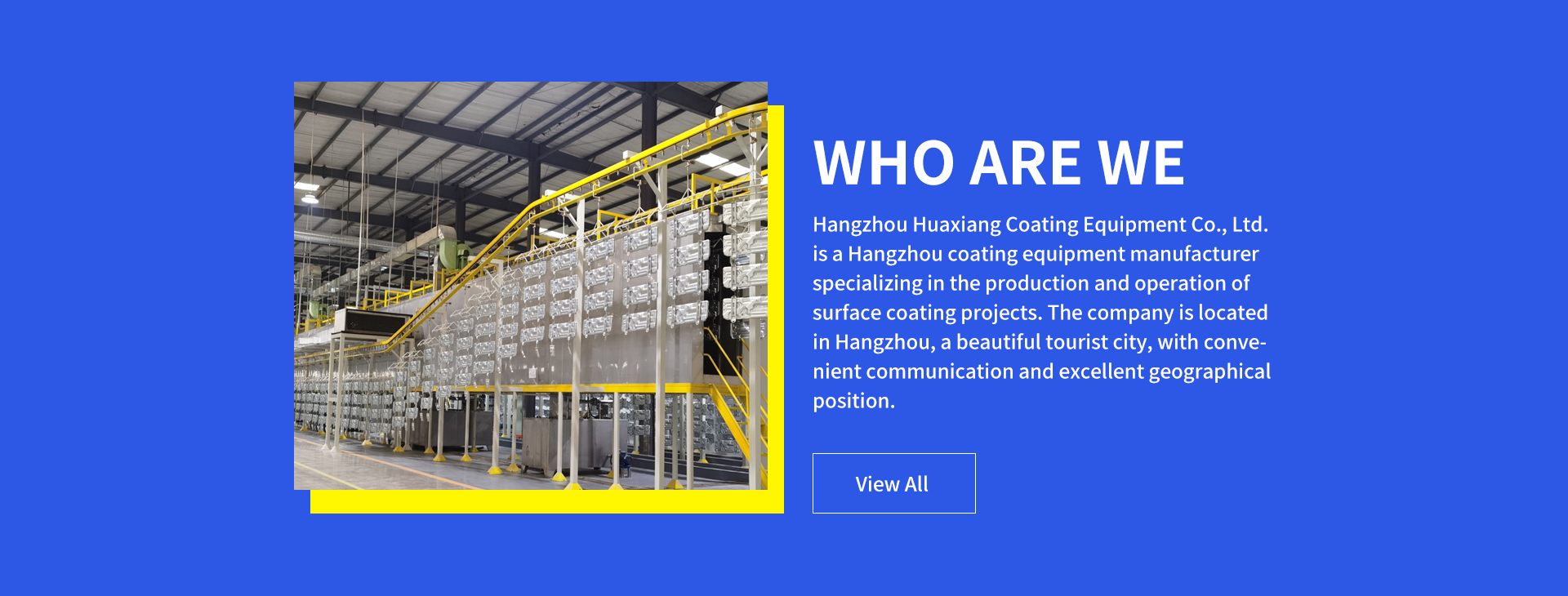

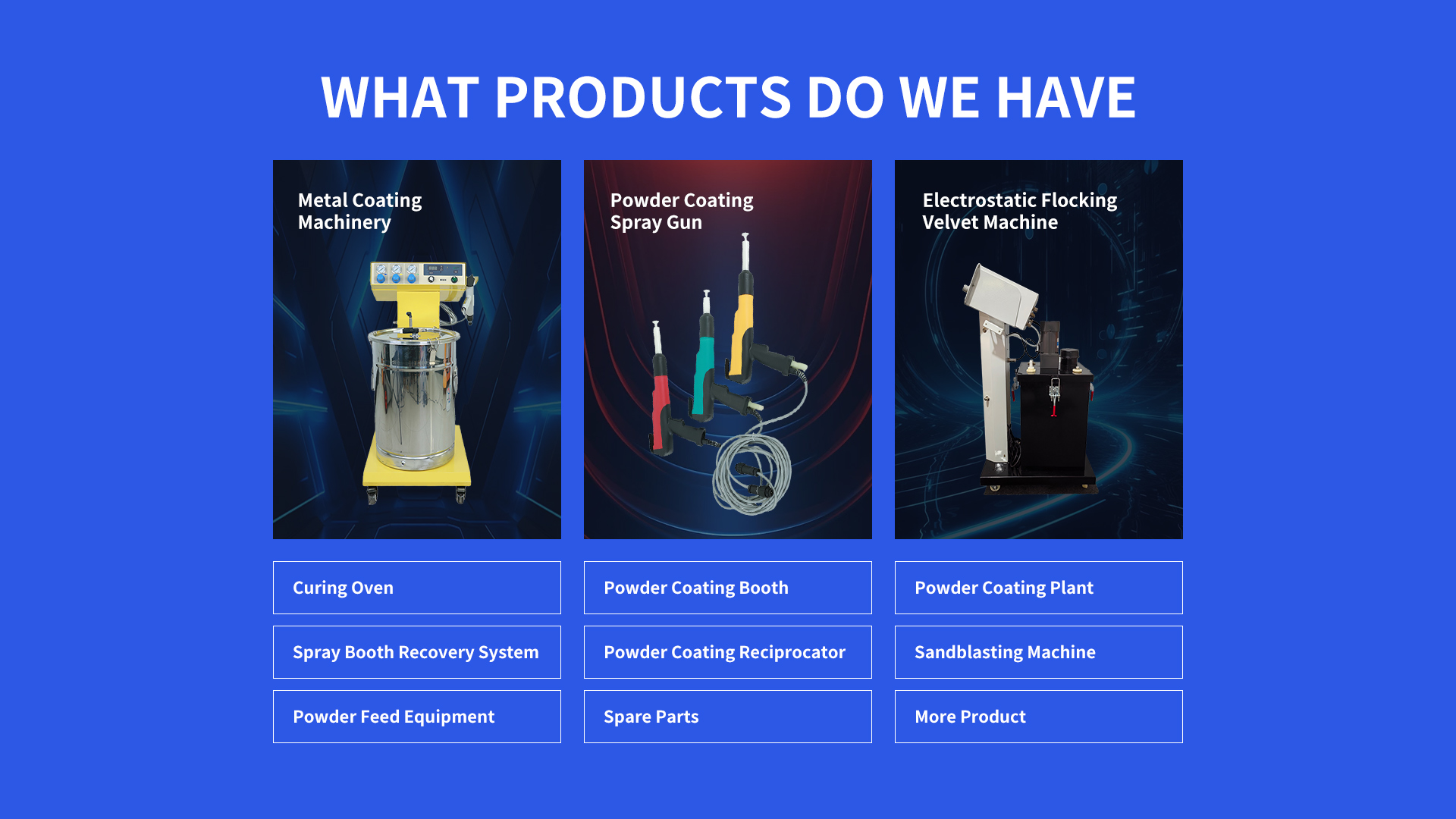

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com